We proudly look back on the final event of the BiDeBA project. The turnout was impressive, with attendees from industry, government, defense, and educational institutions all coming together to witness the results of our collaborative innovation...

The project was carried out by a strong international consortium: ACRATS, Avans University of Applied Sciences, Flanders Make, TU Delft, and GMI Aero. Together, we developed an innovative biobased repair solution for aerospace applications.

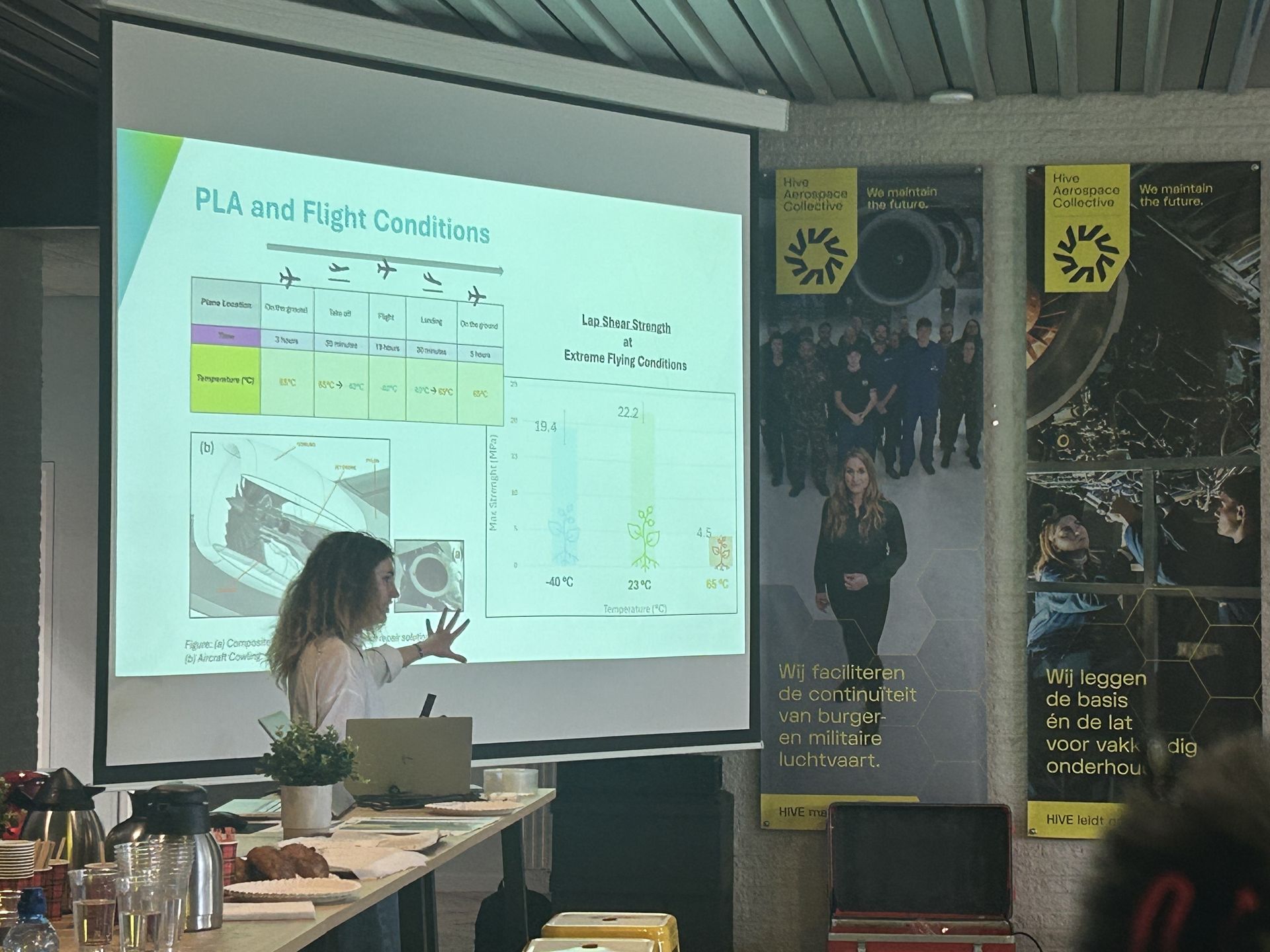

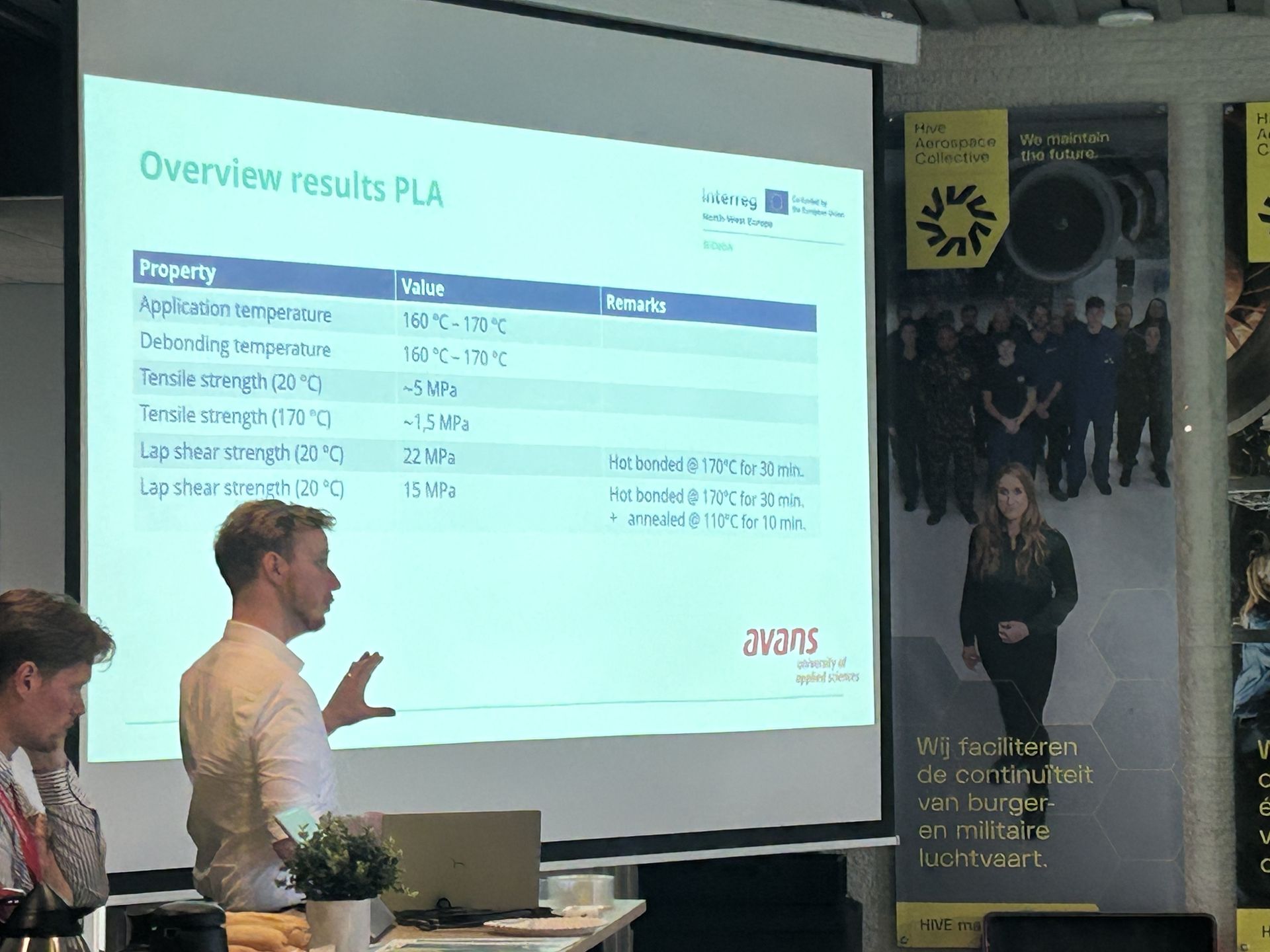

During the event, we demonstrated our technology on an Airbus A320 radome. The system uses a biobased resin that becomes fluid when heated. Once applied, it fully cures within one hour. What makes it especially unique is its reversibility: after curing, it can be reactivated and removed by applying heat — even with a simple lamp or hairdryer.

This makes the material ideally suited for temporary structural repairs in aircraft: strong enough to allow for a single safe flight to a maintenance facility where a permanent repair can be carried out.

This project was made possible thanks to the support of Interreg North-West Europe. As a European program that promotes cross-border innovation and sustainability, Interreg NWE enabled us to bring together expertise, technology, and resources across regions. Their contribution was essential to making BiDeBA the success it has become.

We sincerely thank Interreg NWE for their support, and all attendees for their valuable insights, questions, and enthusiasm. While this event marked the end of the project, it is just the beginning of exploring new applications for biobased, smart materials in high-tech industries.

Check out the recap video here.

Interested in this technology or want to learn more about the material?

Please contact:

Rick van Opdorp

Rick will connect you with the appropriate expert or organization.