Drawing inspiration from the past to shape the future of sustainable adhesion

What can archaeology teach us about the future of adhesive technology?

The BiDebA project combines scientific innovation with ancient insight to develop sustainable, bio-based, and debondable adhesives for industrial use.

In this blogpost, we explore how red ochre, a pigment used by early humans, can do more than just add colour...

A Colour with a Legacy

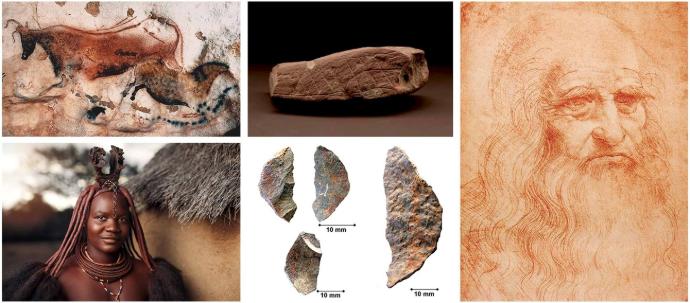

For over 300,000 years, humans have used pigments not only for art and expression, but also for practical purposes. Among these, red and purple pigments have consistently held a special place across cultures and time periods. In nature, red pigments are often derived by grinding iron-rich rocks into powder. The specific shade depends on the concentration of iron oxides. Red ochre, in particular, has been used for a wide variety of purposes—from artistic expression and body painting to cosmetics, funerary rituals, hide tanning, sun protection, and even mosquito repellent.

This versatile pigment has stood the test of time. From the majestic cave paintings of Lascaux to the self-portraits of Leonardo da Vinci, ochre has coloured human history in remarkable ways.

But what if this ancient pigment could also help us build the adhesives of the future?

A Clue from the Past

Recent molecular studies of archaeological materials have uncovered a fascinating pattern: early humans often combined iron oxides like hematite with natural binders such as resins or tars. The result? Adhesives that were not only sticky—but also remarkably strong, resilient, and durable. These findings sparked our curiosity. Could this prehistoric strategy help solve a modern challenge—creating strong, sustainable, and debondable adhesives?

Testing the Theory:

Hematite as a Modern Additive

Inspired by this ancient practice, we set out to investigate whether hematite, a type of iron oxide found in red ochre, could enhance the performance of natural adhesives. Using materials such as birch tar, rosin, hide glue, and beeswax, we recreated archeology-inspired adhesives. We then subjected these samples to rigorous testing, including lap shear tests and rheological measurements. What was the impact of hematite on the mechanical, thermal, and structural properties of the adhesives?

The results were striking. Hematite noticeably improved shear strength. It also had an intriguing effect on thermal behaviour: it lowers the melting temperature of the rosin–beeswax blend, reduces the energy needed for melting in both birch tar and the rosin–beeswax blend, and allows birch tar to debond at a lower temperature. These changes could make such bonding solutions more energy-efficient to apply and easier to use and recycle.

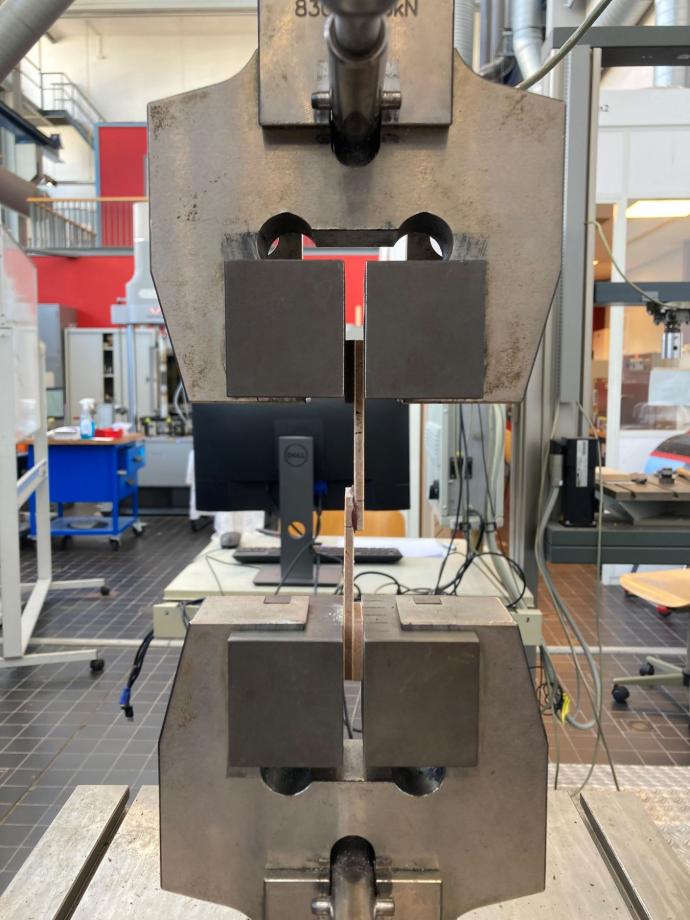

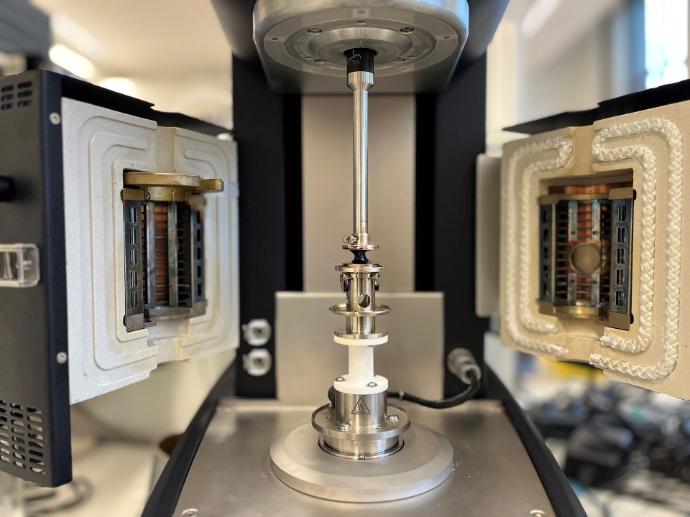

From left to right: Mechanical testing of recreated archeo-inspired adhesives. Lap shear test to determine adhesive strength. Rheological measurement to determine adhesive debonding temperature.

A Smart Additive for a Sustainable Future

In conclusion, hematite acts as a smart filler: it enhances adhesive strength, improves energy efficiency, and integrates seamlessly into the adhesive matrix without altering its chemical structure. These properties make it a valuable ingredient for tailoring bio-based adhesives to modern needs, especially when sustainability, efficiency, and versatility are key.

Our research shows that the materials of the past still have much to offer. By revisiting ancient practices through a scientific lens, BiDebA demonstrates how history can inform innovation. Sometimes, the smartest solutions are the ones humanity discovered long ago—hidden in plain sight, in the red dust of the earth.